DUROXITETMRepile welding composite plate

Product Features

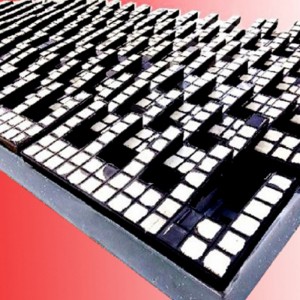

1. The Duroxite™ product range is designed to withstand different types of wear, such as surface erosion, impact, high temperature, metal-to-metal and corrosive wear, etc. Duroxite™ is particularly suited to resist sliding wear of unusually hard particles, such as quartz-containing ores.

2. Duroxite™ 300 utilizes a specially formulated wear resistant material. The composite overlay has an ultra-high content of ultra-fine complex and phase boron carbide with grain size finenesses of up to 500 nm. boron carbide is approximately 200 times finer than conventional chromium carbide.

Scope of Application

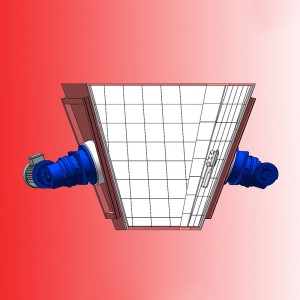

Fan blade, coke vibrating screen screen plate, machine shell, sinter ore conveying trough, powder separator guide vane, vibration or spiral conveyor feeder liner, blast furnace feed hopper, ball mill feeding system.

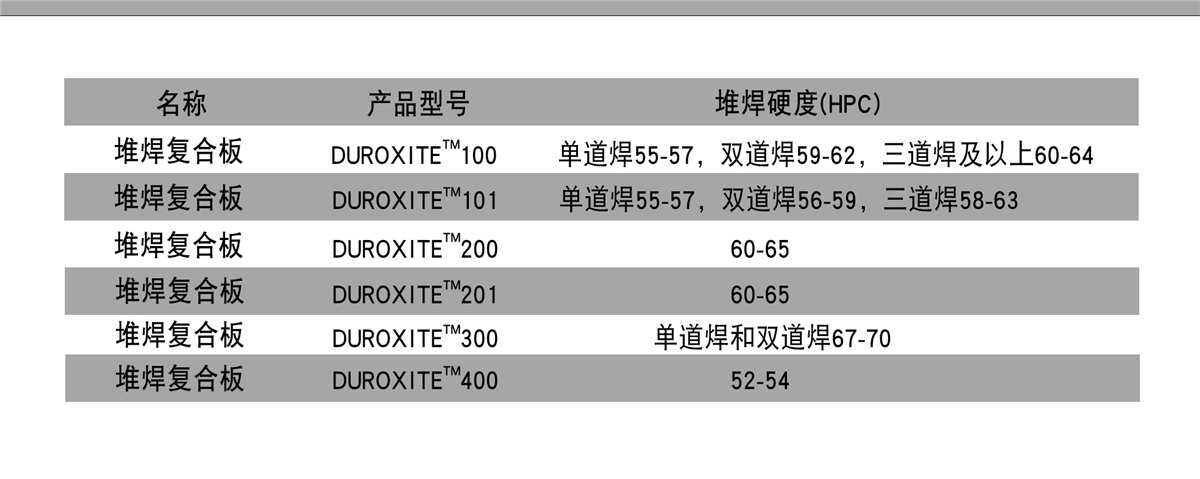

| Name | Product model | Welding hardness(HPC) |

| welding composite plate | DUROXITE™100 | Single welding welding 55-57, double welding 59-62, three welding and above 60-64 |

| welding composite plate | DUROXITE™101 | Single welding 55-57, double welding 56-59, three welding 58-63 |

| welding composite plate | DUROXITE™200 | 60-65 |

| welding composite plate | DUROXITE™201 | 60-65 |

| welding composite plate | DUROXITE™300 | Single and double channel welding 67-70 |

| welding composite plate | DUROXITE™400 | 52-54 |