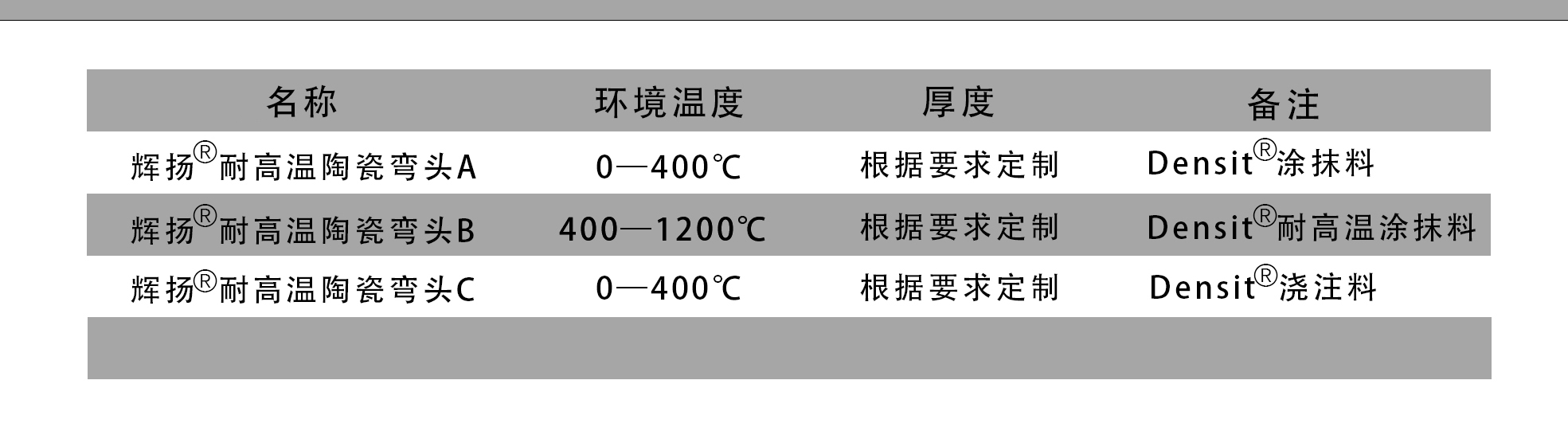

HuiYang®High temperature ceramic elbow(0-1200℃)(Coated, poured)

Product Features

1. Good abrasion resistance, which is incomparable to that of metal materials.

2. Due to the casting or coating molding process, the overall structure has no gaps and can be constructed on-site for any equipment geometry.

3. Long service life, which can reduce costs and avoid unplanned downtime and late maintenance investment caused by wear and tear.

4. Best thermal shock resistance, the material has a low coefficient of thermal expansion and high compressive strength, can accept 1100 ° water cold and hot shock more than 35 times.

5. It can be made into any non-standard prefabricated parts to realize on-site quick assembly and disassembly.

Scope of Application

Large pipes, elbows; fan shells; valves, mills and separators, and other serious scouring and abrasion parts.