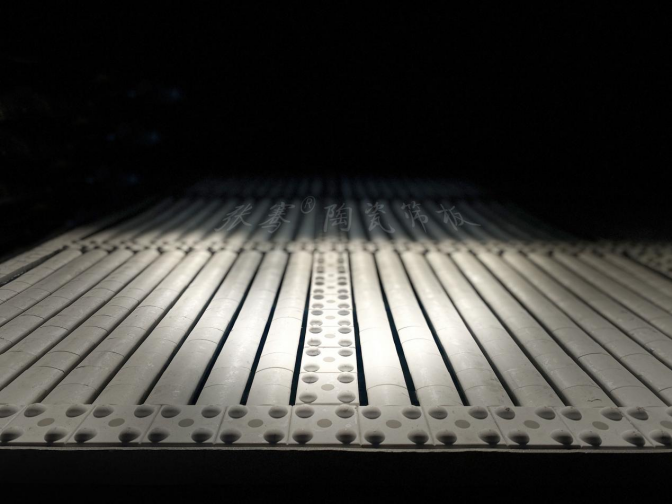

In the coke plant, vibrating screen using traditional cast steel screen plate for coke screening, due to coke polygonal body wear, the service life of the cast steel screen plate is only 3-6 months, and the use of wear-resistant ceramic screen plate for screening, especially in the high-frequency vibration environment, ceramic bonding has become a major problem; when high-frequency vibration and high temperature exist at the same time, it is the ceramic bonding problems in the tower of the tip. This is because the ceramic is an inorganic material, while the steel plate is a metal material, the two will be bonded together not only requires a superior bonding process, but also needs to have a superb bonding technology. In the coke screening process, the adhesive not only to withstand the mechanical hammering of the direction of force, but also to cope with high temperatures brought about by the peeling force role, need to be suitable for high temperature materials and technology to solve.

In the face of this desert field, which has never been seen before and will never be seen again, we rise to the challenge, and our ZHANGQIAN® ceramic sieve plate lives up to its name and solves these difficulties, as shown in the following aspects:

1, high bonding strength: the use of imported adhesives, through a special process for bonding, to meet the carbon steel, stainless steel, aluminum and other metal-based materials expansion coefficient of different plastic changes caused by the bonding strength of up to 15.9MPa.

2, long service life: service life of 12-24 months, is the traditional cast steel screen plate 4 times.

3、Enhance production efficiency: Due to the long service life, there is no need to replace the screen plate frequently, which directly enhances the production efficiency and reduces the downtime and maintenance cost.

4, high temperature resistance: through the exquisite bonding process, the use of imported adhesive bonding, high temperature resistance of 180 ℃, and can work stably in the high-frequency vibration environment.

5, wear-resistant: the use of 92% AL2O3 high wear-resistant ceramic material made of screen plate, the hardness of up to 1100-1400HV, can significantly reduce the wear and tear, to avoid the use of the process of wear and tear caused by the sieve holes become larger.

6, easy to replace: ZHANGQIAN ® ceramic screen plate in the installation holes around the wear-resistant treatment to extend the service life of the mounting holes, the installation of the installation only need to remove the bolt to complete the replacement, greatly simplifying the replacement process.

The application of ZHANGQIAN® ceramic screen panels in high-frequency vibration and 180℃ high-temperature coke screening not only solves the problems of traditional cast steel screen panels under extreme conditions, but also brings significant economic benefits to coke plants. In the future, Huiyang Technology will continue to be committed to technological innovation and service enhancement, to provide customers with more efficient and reliable solutions, and help more enterprises to gain advantages in the fierce market competition. We look forward to working hand in hand with more partners to meet future challenges and create a better tomorrow.

Post time: Sep-23-2024