Roller is an important part of the belt transportation system, its structure is simple and compact, sealing performance is extremely superior, even in the dust concentration is very large and very wet workplace can also be used, with the composition of the belt conveyor, widely used in coal, coking, mining, metallurgy and other industries to transport bulk materials or pieces of goods.

While conveying materials, the friction and wear of rollers has been a headache. An iron and steel group coke, iron mixed load on the blast furnace belt conveyor, 400 meters long, tape ST2500, bandwidth 1400mm, belt speed 2.0m/s, inclination angle of 10.7 °, conveying capacity of 1600t / h, the drive power of 4 × 220Kw, day after day of high load rotation and friction, if you use the conventional rubber-coated rubber rollers (14mm thick, for example), just 4 months roller Friction and traction between the belt body will be sharply reduced, the surface will appear serious wear and rupture, it will cause the conveyor belt to run off and slip, as we all know, the belt run off will not only cause the roller to run away from the axis of the rollers, roller bearings are damaged, but also cause the material spilled to the return belt, caused by the roller and the belt of the abnormal abrasion between the belt, which greatly reduces the efficiency of the entire conveying system, so how to enhance the friction and traction of the So how to improve the friction traction of the roller is a problem worth thinking about!

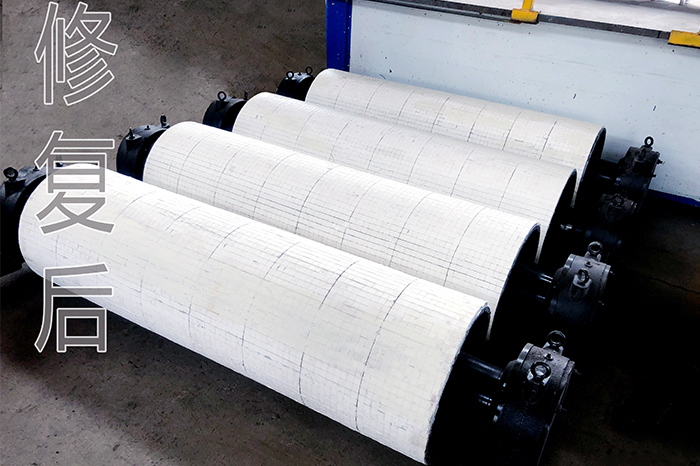

How to reduce wear and tear to improve equipment utilization, our company has been on the road, through years of accumulated experience in wear management and control, our company chose to increase the friction coefficient of the way, through a special arrangement and gluing process in the roller surface coating a layer of 92% AL2O3 high wear-resistant ceramics, specifications of 17.5 * 17.5mm or 20 * 20mm, so that the belt body and the contact behavior of the rollers into a flexural body Contact with super elastic body, to improve the characteristics of the friction transmission contact surface, thereby increasing the roller surface friction factor, and ultimately improve the friction force.

The service life of the rollers with ceramic patches directly increased 15 times, from the original 3-4 months to 5-8 years, effectively solving the problem of short service life, serious wear and tear of the rollers, which requires frequent overhauling and maintenance, and greatly saves manpower, material and labor costs and other effective resources.

Although we have been successful, but we know that there is no one-size-fits-all solution to wear, we have to reach out to more specialties in order to make our continuous development and growth.

Post time: Mar-25-2024