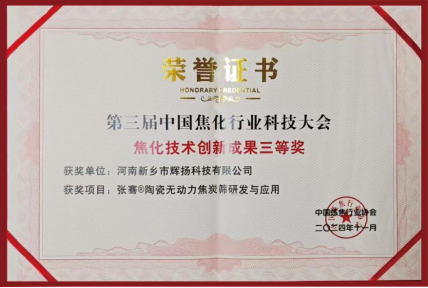

The 3rd China Coking Industry Science and Technology ConferencewassuccessfullyheldinChengduCongratulations to our company for winning the third prize for innovative achievements in coking technology

The venue of the 3rd China Coking Industry Science and Technology Conference

diplomat famed for exploits in Inner Asia®The ceramic unpowered coke screen,through its innovative design and perfect integration with ceramic materials,significantly reduces the crushing rate of coke,manifested in the following aspects:

1.Non powered design:Zhang Qian®The ceramic unpowered coke screen uses the gravity and inertia of the material itself for screening,which not only saves electricity costs,but also eliminates maintenance projects such as installing exciters,motors,couplings,etc.More importantly,the working environment has made a qualitative leap,and the days of dust flying are gone forever.Bringing safety and health to technological progress.

2.Reduce coke breakage rate:Due to the absence of kinetic energy output and vibration,the coke breakage rate also decreases.Compared to the vibration screen,the collision probability of coke is reduced by 90%,which can reduce the coke crushing rate by about 3‰and increase the quality and sales value of coke in production enterprises.

3.Material advantage:Zhang Qian®The contact material of the ceramic unpowered coke screen is made of alumina ceramic,which has wear-resistant and corrosion-resistant properties.Compared with traditional metal screens,ceramic screen strips are wear-resistant and have a service life of not less than five years,avoiding coke blockage caused by screen deformation or wear,and reducing coke breakage caused by blockage and compression.

4.Sliding motion:Reasonable tilt angle and smooth ceramic surface allow coke to slide on the screen surface,reducing friction with the screen surface and minimizing coke breakage caused by collision or compression.

5.Curved design of feed inlet:The feed inlet adopts a curved design to ensure that the material enters the screen surface with tangential flexibility at a contact angle of less than 20°,resulting in minimal impact and reducing the risk of crushing caused by impact.

After more than ten years of deep cultivation in the coking industry, our company won the “Third Prize for Coking Technology Innovation Achievements” award project “Zhang Qian” at this conference ® Research and application of ceramic unpowered coke screen. Our company will continue to develop advanced and applicable energy-saving and carbon reduction technologies, accelerate the transformation and upgrading of ultra-low emissions, and continuously strive forward in the coking industry.

As a domestic manufacturer of engineering materials, our company always considers product quality and economy as the primary factors. We have established a technical exchange platform with ITW, SSAB, EDEM, and ROSTA companies for the application of wear-resistant materials in engineering from multiple physical properties, environments, and perspectives. Implemented information exchange for design, management, and production. Improved the operational efficiency of the enterprise and continuously accelerated the pace of product development.

Continuous innovation and improvement are the driving force behind our company’s continuous progress. With the continuous maturity of technology and the expansion of application fields, we will continue to develop more efficient and environmentally friendly solutions, helping multiple industries such as steel, chemical, energy, and environmental protection to achieve industrial upgrading and move towards a more intelligent and green future.

Post time: Nov-18-2024