In today's highly competitive industrial environment, ensuring production efficiency and product quality while effectively controlling costs is the key to sustainable development. For the iron and steel and energy industries that rely on coke as a core raw material, reducing the coke crushing rate is not only a necessary condition to improve production efficiency, but also an important link to enhance economic efficiency and achieve optimal use of resources.

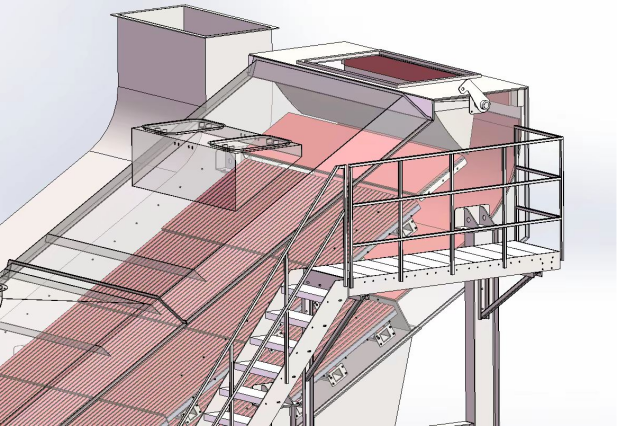

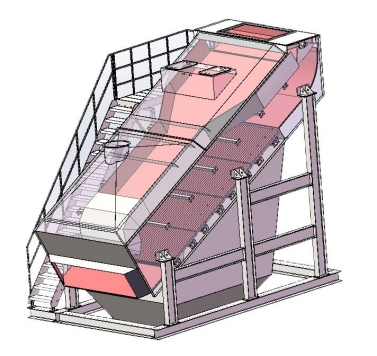

In a coke plant in Shanxi, coke screening using the traditional vibrating screen, vibrating screen working principle is based on mechanical vibration or electromagnetic vibration, through the vibration power to make the coke placed on the screen surface according to the size of the particle size of the separation, repeated vibration will make the coke in the screen surface by the collision and throwing, increase the probability of mutual collision between the coke, which aggravates the coke crushing, and the vibrating screen screen surface tilt angle, screen wear and improper installation will lead to the coke crushing, and the tilt angle, wear and tear and improper installation will lead to the coke crushing. The angle of inclination of vibrating screen surface, wear and tear of screen mesh and improper installation will all lead to the increase of coke crushing rate. However, Zhangqian® ceramic powerless coke screen can reduce the coke crushing rate, mainly due to its superior design characteristics and material properties, specifically in the following aspects:

1. Powerless design: Zhangqian® ceramic powerless coke screen uses the material's own gravity and motion inertia for screening, without the strong vibration and impact generated by the motor drive, compared with the vibrating screen coke collision rate reduced by 90%, increasing the value of coke merchandising for the production enterprise.

2. Material advantage: Zhangqian® ceramic powerless coke screen uses aluminium trioxide ceramics in contact with materials, which has wear-resistant and corrosion-resistant properties. Compared with the traditional metal screen mesh, the ceramic screen bars are wear-resistant, with a service life of not less than five years, which avoids coke jamming due to the deformation or abrasion of the screen mesh, and reduces coke crushing due to blockage and extrusion.

3. Gliding movement: reasonable inclination angle and smooth surface of ceramic make coke glide on the screen surface, reduce friction with the screen surface, and reduce coke crushing caused by collision or extrusion.

4. Curved inlet design: The inlet adopts a curved design to ensure that the material enters the screen surface tangentially and flexibly with a contact angle of less than 20°, which has little impact and reduces the risk of crushing due to impact.

ZHANGQIAN® ceramic powerless coke screen significantly reduces the coke crushing rate and improves the quality and sales value of coke through the perfect fusion of its innovative design and ceramic material. According to the feedback from the customers, the crushing rate of finished coke is reduced by 3‰-7‰.

Of course, continuous innovation and improvement is the driving force for our company to keep moving forward. With the continuous maturity of technology and the expansion of application fields, we will continue to develop more efficient and environmentally friendly solutions to help many industries, such as iron and steel, chemical industry, energy and environmental protection, to achieve industrial upgrading and move towards a smarter and greener future.

Post time: Jun-27-2024