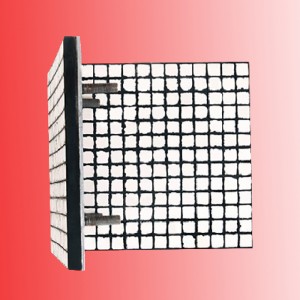

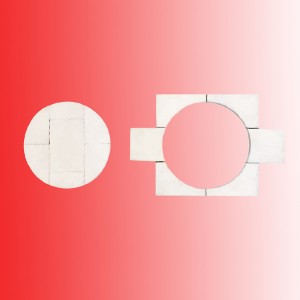

Rubber ceramic steel plate composite liner

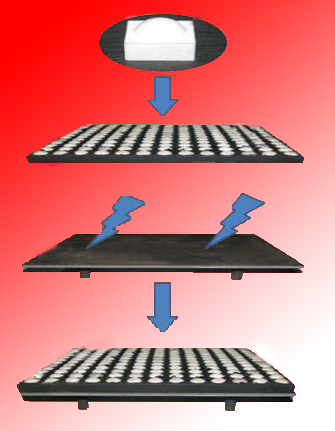

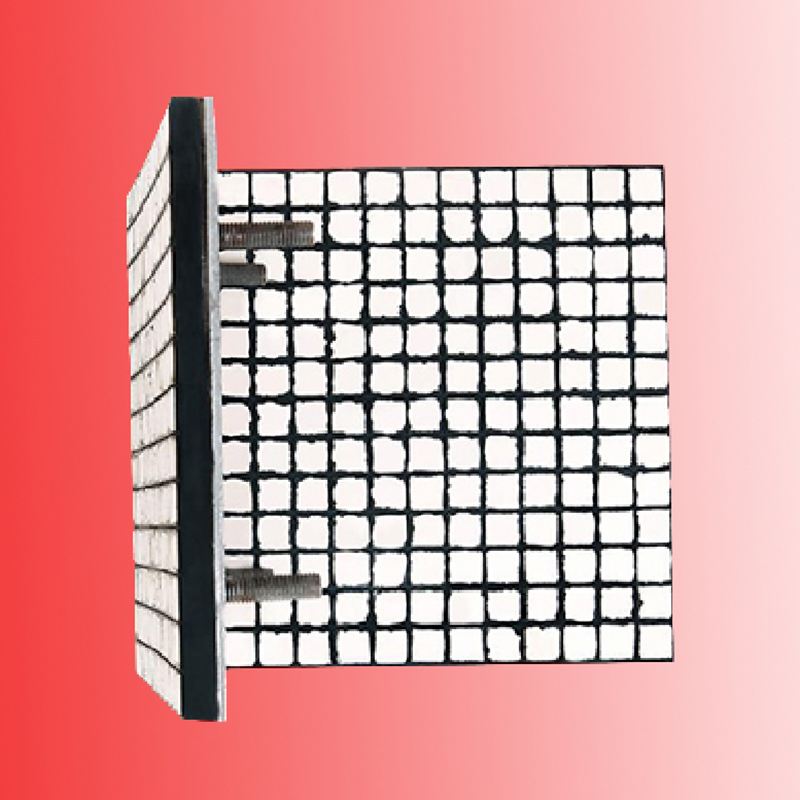

Product Structure

The steel plate, rubber and ceramic together in the mold to complete the vulcanization bonding process. The bolts are customized according to the customer's needs, and the process of using them is easy to realize and the workload is smaller.

Product Features

1. 92% aluminum trioxide is used as the wear-resistant surface.

2. Highly elastic rubber can absorb mechanical impact.

3. Strong tear resistance. 4.

4. Working condition ambient temperature -35℃-60℃. 5.

5. Technical support from Japan Rion, USA Dow Corning and Lloyd's.

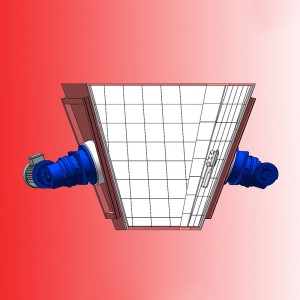

Scope of Application

1. Iron and steel industry

(1) Silos, hoppers, tee trolleys, sintering mixing and mixing drums.

(2) Baffle plate, weighing hopper.

(3) Vibrating screen beams, feeding parts, in and out of the grain end.

(4) Feeder, gate part.

2, Coking . Coal industry Power industry

(1) Silo, hopper, discharge end of the granting part.

(2) Vibrating screen beam, feeding part, inlet and outlet end.

(3) Material retaining plate.

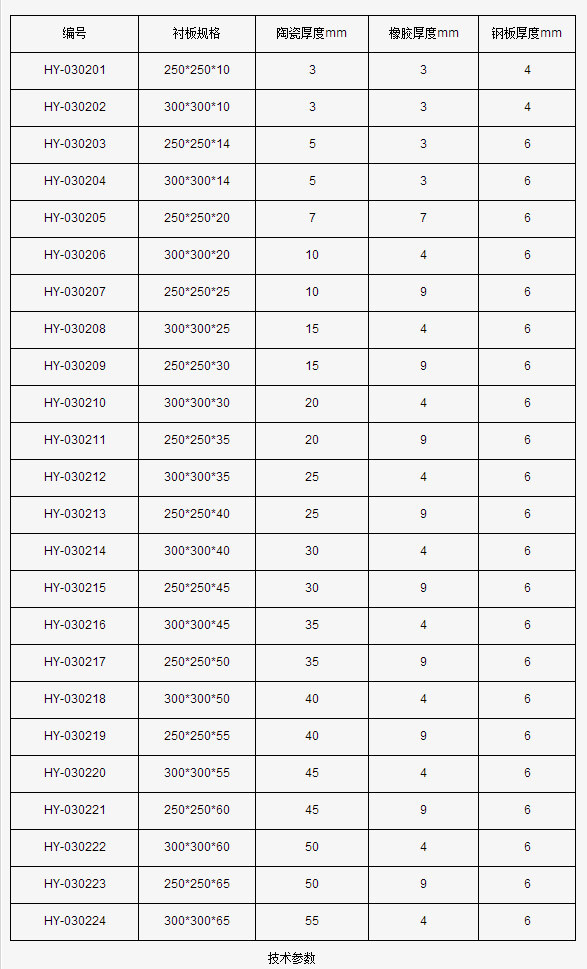

| 编号 | 衬板规格 | 陶瓷厚度mm | 橡胶厚度mm | 钢板厚度mm |

| HY-030201 | 250*250*10 | 3 | 3 | 4 |

| HY-030202 | 300*300*10 | 3 | 3 | 4 |

| HY-030203 | 250*250*14 | 5 | 3 | 6 |

| HY-030204 | 300*300*14 | 5 | 3 | 6 |

| HY-030205 | 250*250*20 | 7 | 7 | 6 |

| HY-030206 | 300*300*20 | 10 | 4 | 6 |

| HY-030207 | 250*250*25 | 10 | 9 | 6 |

| HY-030208 | 300*300*25 | 15 | 4 | 6 |

| HY-030209 | 250*250*30 | 15 | 9 | 6 |

| HY-030210 | 300*300*30 | 20 | 4 | 6 |

| HY-030211 | 250*250*35 | 20 | 9 | 6 |

| HY-030212 | 300*300*35 | 25 | 4 | 6 |

| HY-030213 | 250*250*40 | 25 | 9 | 6 |

| HY-030214 | 300*300*40 | 30 | 4 | 6 |

| HY-030215 | 250*250*45 | 30 | 9 | 6 |

| HY-030216 | 300*300*45 | 35 | 4 | 6 |

| HY-030217 | 250*250*50 | 35 | 9 | 6 |

| HY-030218 | 300*300*50 | 40 | 4 | 6 |

| HY-030219 | 250*250*55 | 40 | 9 | 6 |

| HY-030220 | 300*300*55 | 45 | 4 | 6 |

| HY-030221 | 250*250*60 | 45 | 9 | 6 |

| HY-030222 | 300*300*60 | 50 | 4 | 6 |

| HY-030223 | 250*250*65 | 50 | 9 | 6 |

| HY-030224 | 300*300*65 | 55 | 4 | 6 |

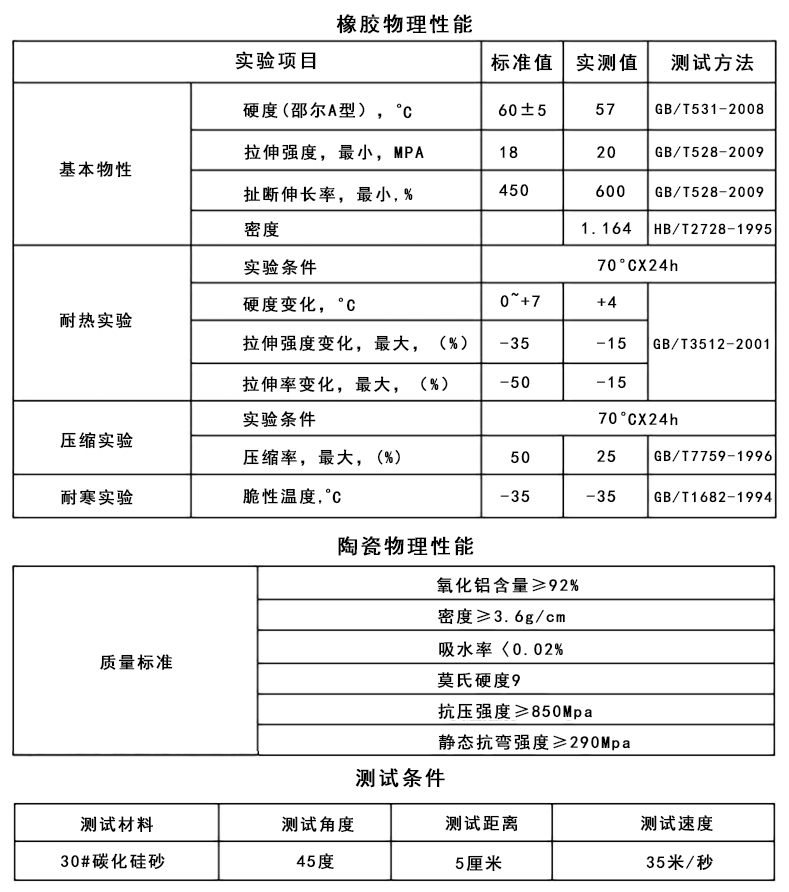

Physical properties of rubber

|

Experimental project |

Standard value |

Measured value |

Test method |

|

|

Basic physical properties |

Hardness (Shao Er Type A), ℃ |

60±5

|

57 |

GB/T531-2008 |

|

Tensile strength, minimal, and MPA |

18 |

20 |

GB/T528-2009

|

|

|

Break elongation, minimum,% |

450 |

600 |

GB/T528-2009

|

|

|

density |

|

1.164 |

GB/T1682-1994

|

|

|

Heat resistance experiment |

experimental condition |

70°CX24h

|

||

|

Hardness change,° C |

0~+7 |

+4 |

GB/T3512-2001

|

|

|

Tensile strength variation, the maximum, (%) |

-35 |

-15 |

||

|

The tch rate change, maximum, (%) |

-50 |

-15 |

||

|

Compression experiment |

experiment condition |

70°CX24h | ||

|

Compression rate, maximum, (%) |

50 |

25 |

GB/T7759-1996 | |

|

Cold tolerance experiment |

Fragile temperature, and ° C |

-35 |

-35 |

GB/T1682-1994 |

Physical properties of ceramics

| Quality standard | Aluminum oxide content≥92% |

| density≥3.6g/cm | |

| water absorption <0.02% | |

| Moh's hardness 9 | |

| compression strength≥850Mpa | |

| Static bending strength≥290Mpa |

Test condition

| Testing materials | Test angle | Measuring distance | Test speed |

| 30#Silicon carbide sand | 45° | 5cm | 35m/s |